View This Article in BOSS Magazine

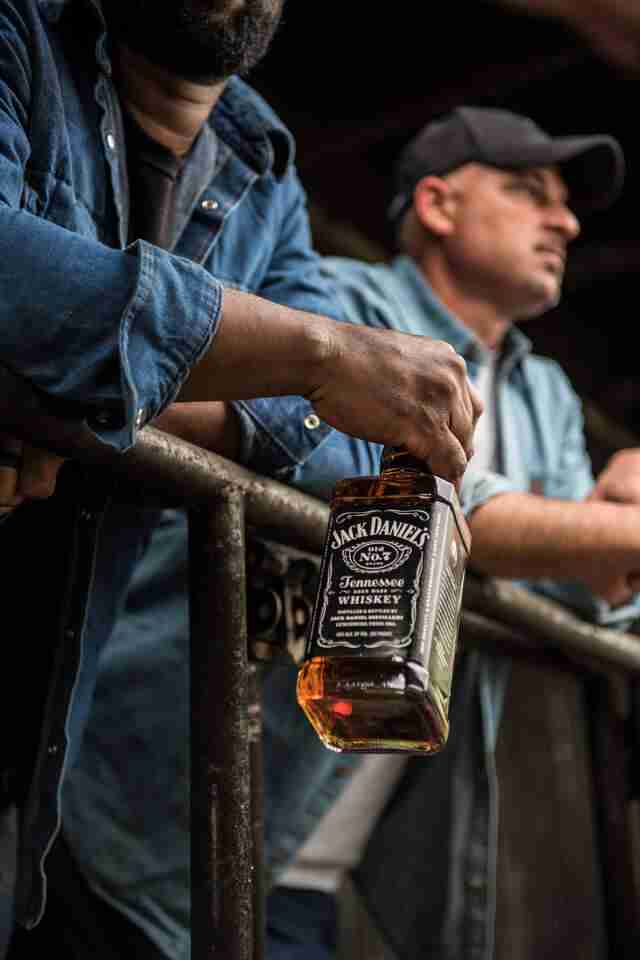

A painstakingly curated blend of the old and new banks delicious fire in the hearts of devoted drinkers in over 170 countries worldwide.

Tennessee whiskey lovers, consider this our heart- and soul-warming gift to you in these early winter days. We can’t teleport you to Lynchburg to experience the magic firsthand, but we can connect you to the nation’s premiere whiskey crafter through one of its most influential hands-on execs. Put your feet up, sit back, and enjoy. We won’t judge you for settling in with a glass of Old No. 7 in hand. Matter of fact, we encourage it …

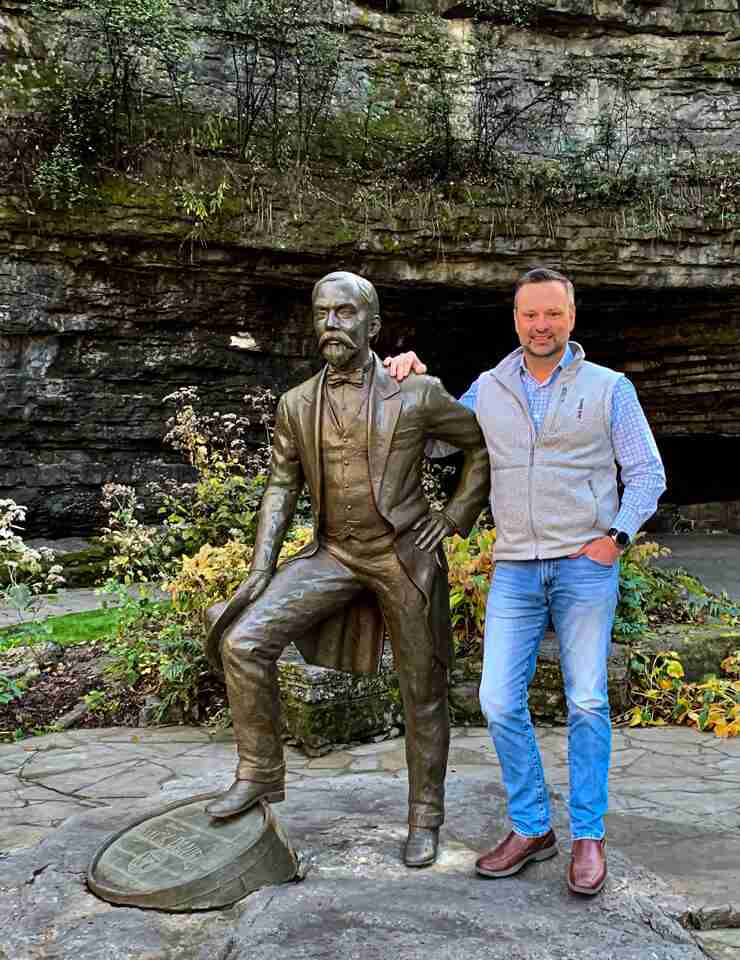

… and we’re pretty sure Jack Daniel’s Senior Vice President and General Manager of global supply chain, Larry Combs, does too. We recently sat down with him to get a “combover” of some of the 154-year-old company’s advancements in technology, as well as an inside look at some of the integral hand-crafted touches that make a sip of Jack in Sacramento indistinguishable from a sip of Jack in Seoul.

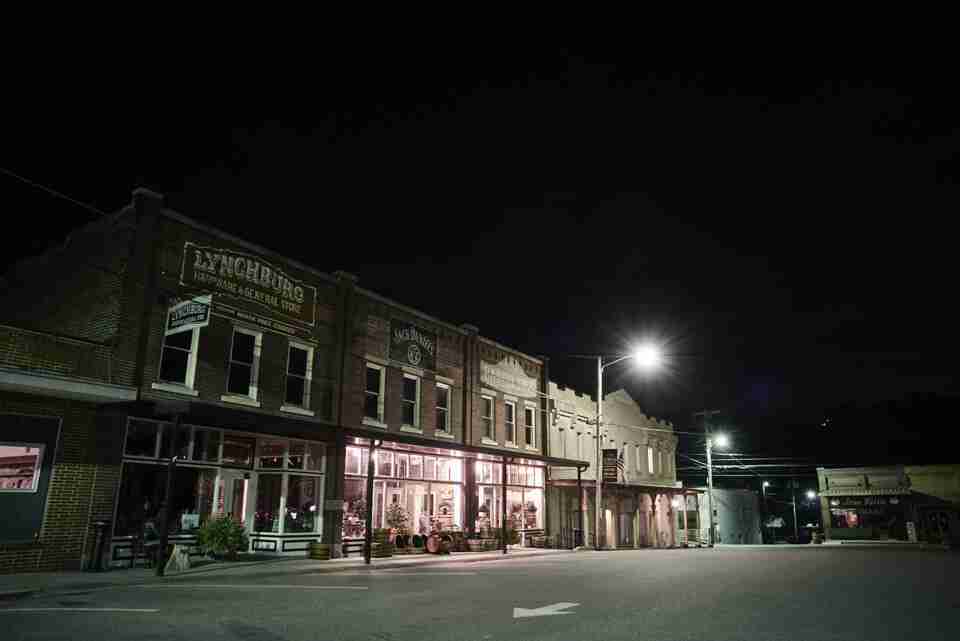

Before we get to how they do that, let’s consider why what they make truly matters. Lynchburg is a town of just over 650 people. For more than 154 years, every drop of Jack Daniel’s has been made there. Multiple generations of families have made Jack Daniel’s what it is—the world’s best-selling whiskey, and one of the most iconic brands on the planet.

Moore County (pop. 6,300) is where the magic happens, and it’s also the first county in Tennessee to ensure that every child in their elementary schools has a Chromebook. Every sport, every Scout troop, and every civic organization in Lynchburg is healthily sponsored every year. The high school has a newly renovated auditorium, and the community center has its own public pool. The senior center never pays for capital improvements. Leaders of the local Head Start program pay a whopping $1 for rent. There’s even an animal shelter in the town. All of this, and more, is thanks to Jack and its sponsorship of the town that brings each sweet, smoky drop of its success to life.

We’ll get to how the company recently spent over $400 million in capital to add capacity right after we note they invested $25 million on employee facilities that include an employee resource center, contemporary gym, on-site clinic, and amenities that make their working environment comfortable and productive. Workers get a pension and 401(k). With employee engagement figures at the top of the charts, Jack Daniel’s isn’t just a “company town” employer, but an employer attracting top-shelf talent. There’s love in what they do, as evidenced by entire families, as many as six generations back, working to bring the one and only Jack to the world.

“I can honestly look you in the eye and tell you that you can spend your career here, and so can your grandkids and your grandkids’ kids,” Combs intimated. “We’ve been here for 154 years, and our brand is as much about where we make it as what we make, and it's not unreasonable to think we'll be here another 150 or so. With our lineage and history, there’s loyalty from the employees to us and us to them that's hard to replicate.”

Local knowledge yields global devotion

One of Combs’ favorite quotes is from Jack Daniel himself. “Every day we make it we’ll make it the best we can.” Doing exactly that is how the brand eclipsed Johnnie Walker as the world’s best-selling whiskey. This year it became No. 1 in the United Kingdom. (You’re not hearing things; that’s just the sound of pearls being clutched in Balmoral.)

A blend of tradition and technology creates the unmistakable Jack Daniel’s taste, and a lot of the action begins in their vertically integrated supply chain. As the only major distiller that makes its own barrels, the company buys 2,500 to 3,000 logs annually from individual loggers to supply its mill networks. “We pick the logs, which are processed into stave and heading pieces. Those pieces are supplied to our two cooperages, one in Louisville, Ky., and one in Decatur, Ala.,” Combs explained.

“We've made quite an investment in technology and automation around safety, yield, and efficiency. Those pieces are processed, defected, shaped properly, and then assembled into barrels and then those barrels are shipped directly to the distillery for filling. Between those two cooperages we can make about a million barrels a year, and that’s about how many we’ll need for Jack Daniel's here in a couple years, so we'll be adding to that capacity down the road before too long.

“We own that end to end, and we pay close attention to white oak supply, which really is strong, but we’re looking much further down the road and ensuring that we understand sustainability and forest management. We work with the loggers as well as a number of universities, and we helped co-found the White Oak Initiative.” The initiative works to preserve the long-term sustainability of that characteristically American wood.

Oak barrels are the standard for Tennessee whiskey. Like bourbon, Jack is aged in new charred oak barrels. It is also charcoal mellowed using a distillation method from the 1800s called the Lincoln Process after the county in which it originated. “Essentially you reduce the charcoal and filter the whiskey through it. It makes it a little smoother, a little sweeter, and back in that time our technology wasn't as good and the product wasn’t as consistent, and that process helped us to deliver a more consistent product.

“For the charcoal mellowing process we use sugar maple. We source all of that within about 50 miles of the distillery and make all the charcoal on-site. We have two people three days a week working with a controlled burn of the wood, producing the charcoal that we use. Every drop goes through that process, be it Jack Daniel's Black Label or our recent foray into rye whiskey, which is the first new grain recipe at the distillery since Prohibition.”

Three grains, No. 1 grade yellow corn, rye, and malted barley, go into both the main product and the rye. “The malted barley is primarily there to supply the enzymes necessary for conversion. Essentially most of the alcohol is going to come from the starch in the corn and the rye that will be made available to the yeast; that starch has to be converted into sugars and the malts provide the enzymes to do that.”

Jack Daniel’s propagates their yeast in-house from starter created at the end of Prohibition. That’s an 87-year-old, continuous living yeast stream. It’s a sure bet that had Prohibition not interrupted its growth that “mother” would be celebrating its 154th birthday this year.

“Most companies don't do that; most have a commercially provided yeast. For our propagation we take yeast from the prior batch and we'll maintain that living yeast culture,” he noted. “We add some modern technology to it: We DNA fingerprint the yeast so we can keep a very close eye on it, and we keep frozen cultures in 80-below freezers and we check that DNA profile periodically to make sure it’s not drifting. If we ever do see it drift, we’ll reintroduce some of that original yeast culture.”

It takes 9 million bushels of grain every year to make the basic whiskey upon which all of the different flavors, including Gold, Fire, Honey, Apple, Gentleman Jack, and Single Barrel, are based. They essentially start as the same whiskey and are differentiated by aging and finishing.

Using Jack Daniel’s Gold as an example, Combs walked us through the process. “After the whiskey is matured, we dump it from the barrel and put it into a maple wood barrel and finish it for six to nine months in that. That’s how we’ve innovated from a whiskey perspective until the rye, which we introduced three years ago.” Most ryes on the market contain either the legal minimum of rye grain, 51%, or 99%. “From a Jack Daniel’s-style whiskey perspective, because we wanted people to be able to connect it to what they know as Jack, we went with 70%, a little less spicy and charcoal mellowed so it's smoother. We’re pretty proud of that.”

Filled barrels are then taken to one of 93 maturation warehouses in Lynchburg. “We have a few million barrels on the ground. A lot more barrels than people,” he said. Those barrels go in the warehouse and, apart from testing, remain untouched for four to eight years. The large number of barrels and warehouses makes it possible to blend to a remarkably consistent standard.

“I’ve been all over the world, and you can be anywhere—in the tiniest bar in the middle of China—and the odds are they're going to have a bottle of Jack Daniel’s. One thing you know you're going to get, whether you love it, like it, or don't, is it's going to be exactly the same every single time no matter where you go. We’re able to do that both through the quality control as well as being able to pick from such a mix of warehouse locations and barrels and so on, to guarantee exactly the same product every time.”

In 2018 the firm expanded its Lynchburg bottling facility, housing 11 acres under roof. “We shipped about 19 million cases last year, and all of that is from Lynchburg to 170-plus countries around the world,” Combs added.

Daniel’s digitization

Darren and Tracy are responsible for making the charcoal used to mellow the whiskey and create an aspect of the signature Jack taste. As they tend the fire, they sit in their rocking chairs and whittle, and when there are new baby ducks in the ponds around the facility, they scoop them up and raise them to adulthood. There are some things that modern technology just can’t do.

But wherever technology can be used to make a more consistent product and a more efficient operation, it is widely applied. Jack leverages machine learning and artificial intelligence to provide real-time access to data, more real-time decision making, and manufacturing process improvement.

Getting every ounce of worth out of every log used is key to the company’s sustainability and economy plays, and advanced technology is central to those efforts. The pieces of wood that make up the sides of each barrel, the staves, must have precise angle cuts to fit together in the circumference of the barrel. Wide and narrow staves have different angles. Before the most recent modernization effort, large blade wheels would spin and cut one size stave at a time and would be reset for staves of different sizes. Workers would manually inspect every piece of wood for streaks, knots, or other defects, and then use the rotating cutter roughly 30,000 times each day.

“We've leveraged vision systems and machine learning to the point where we are scanning every piece of wood with an array of five cameras, so it'll be from the visual spectrum, infrared, X-ray, ultraviolet, and so on that is scanned on all three surfaces. We teach the computer how to recognize defects. As it gets more data it can better learn and refine how to identify a knot and eventually get to the point where it can remove it within an eighth or 16th of an inch. That now replaces the antiquated process and the people that were in that process,” he said.

Vision systems scan the wood and control automated saws that cut it to length, remove the defects, and measure the yield on every individual piece. CNC machines measure and cut the perfect angle on every stave so each one fits perfectly in the barrel’s circumference. It makes a much higher quality barrel and robs the angels of a bit of their share—the liquid lost to evaporation. By the end of aging, the angels’ share accounts for about 20 to 30% of liquid loss. “We’ve actually reduced that by about 25%, just through better quality wood, better defect removal, cutting that perfect angle, and having a very tightly fit barrel.” The automation also reduced the labor required by 35%.

In the bottling operation, the TrakSYS system collects machinery and performance data in real time, displaying hourly and daily targets, production trends, and system alerts. “We're now approaching 80% (overall equipment effectiveness) on our bottling lines overall in the facility, which is best in class for that kind of operation,” Combs said.

The 24/7 distillery operation is the company’s most automated. “It takes two or three people per shift to run each distillery, so even though it's one of the biggest in the world it's very labor efficient. Over the last six years we fully upgraded all the control technology; there's cameras throughout and everything in the control room is automated. It looks like you're at the launch of the Space Shuttle with the number of screens around, and we’ve gotten to a high degree of automation, labor efficiency, and consistency.”

The people of Jack Daniel’s, supported by corporate parent Brown-Forman, simply love making whiskey. The pride of place and joy of the craft trickles down from the top of the organization into the land that sustains its success, and circles back again as cherished traditions do. Combs summed it up as perfectly as a freshly poured sip of Lynchburg’s finest: “It’s hard to believe that we make every drop of the best-selling whiskey in the world in our little town, but it’s a fact and something we’re pretty proud of.”

Officially registered by the U.S. Government in 1866 and based in Lynchburg, Tenn., the Jack Daniel Distillery, Lem Motlow, proprietor, is the first registered distillery in the United States and is on the National Register of Historic Places. Jack Daniel’s is the maker of the world-famous Jack Daniel’s Old No. 7 Tennessee Whiskey, Gentleman Jack Double Mellowed Tennessee Whiskey, Jack Daniel’s Single Barrel Tennessee Whiskey, Jack Daniel’s Tennessee Honey, Jack Daniel’s Tennessee Fire, Jack Daniel’s Tennessee Apple, Jack Daniel’s Tennessee Rye, Jack Daniel’s Sinatra Select and Jack Daniel’s Country Cocktails. Today, Jack Daniel’s is a true global icon found in more than 170 countries around the world and is the most valuable spirits brand in the world as recognized by Interbrand.

Corporate Office

280 Lynchburg Hwy

Lynchburg, TN 37352

Telephone

Website https://www.jackdaniels.com/

Facebook: https://www.facebook.com/jackdaniels

Twitter: https://twitter.com/JackDaniels_US

YouTube: https://www.youtube.com/user/JackDaniels