View This Article in BOSS Magazine

Automation-focused warehousing experts United Material Handling push the boundaries of what’s possible

Supply and demand for warehousing space is epically imbalanced, with vacancy rates in key U.S. markets stalled below 1%. Logistics operations are under extreme pressure to make the most of every foot of existing space, and new spaces must be equipped at lightning speed. In both scenarios, enterprises across a range of industries are looking to United Material Handling for new ways to meet these unprecedented challenges.

In addition to being experts in facility design, engineering, and building code compliance, UMH is a worldwide manufacturer of products and systems designed to increase operational efficiencies in material handling. Headquartered in Southern California, the firm has distribution facilities there as well as in Toronto, Canada, and research and development in Nanjing, China.

Founded in 2011, what began as a used equipment dealership has transformed into a leading manufacturer of racks, pick module systems, gravity flow systems, guardrails, and mezzanines. Their array of rack equipment includes cantilevered, pushback, drive-in, and selective pallet racks. Essentially, UMH delivers what today’s warehousing and distribution facilities need desperately: space and time.

In addition to warehousing, UMH serves a number of industries, including 3PLs, retail, food and beverage, and manufacturing. The company’s impressive list of clients includes global supply chain consultants Tompkins International, Gilbert Logistics, a 3PL specializing in apparel, footwear, and electronics, and organic household products leader The Honest Company.

“We hold a large amount of stock that we can get to market faster than our competition can,” said UMH owner Ryan Bartlett, who began his entrepreneurial career with $1,000 and a knack for installing warehousing equipment. After a few years of selling and setting up used material handling systems, Bartlett revamped the company, creating a fast-moving warehouse supply and design powerhouse.

What their challengers can deliver in months, UMH can deliver in a matter of weeks. “That makes it advantageous for customers to choose us because they have an extra two or three months of time,” he said. “Whether that’s saving setup time or rent money, it’s a huge advantage for them. That’s why our focus will always be on being faster and more nimble than our competitors. We put ourselves into our customers’ shoes and perform as if we are doing the work for our own warehouse.”

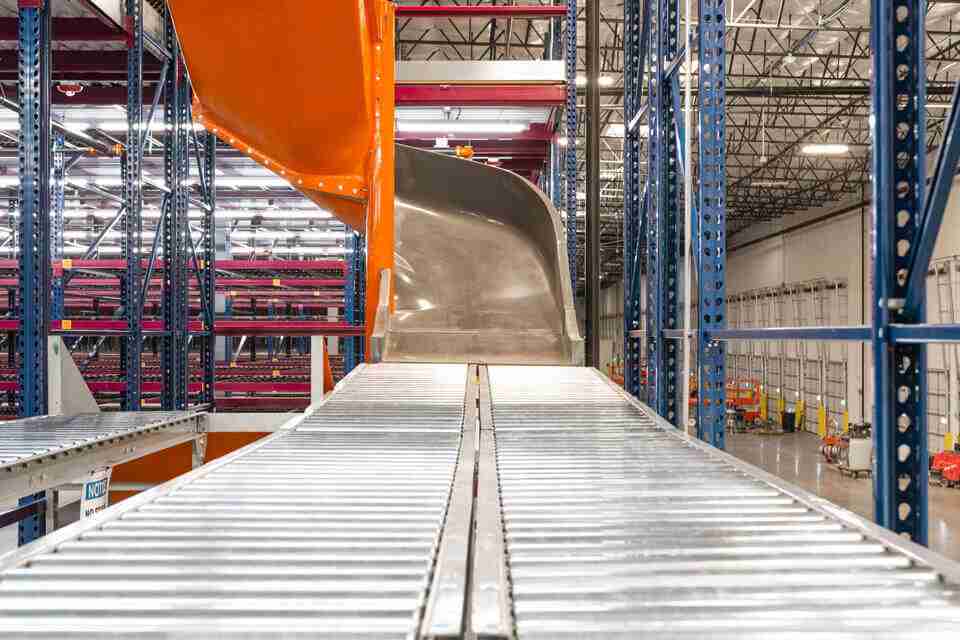

In actuality, they are doing work for their own warehouse. Situated near their Moreno Valley headquarters, they have a 221,000-square-foot facility which acts as storage space for the company’s products as well as a showcase for their engineering and design process. Bartlett describes the expansive building as the company’s improvement grounds. “We didn’t want just a little corner in our space with three pallets trying to demonstrate technology,” he explained. “I wanted to be able to say to customers, ‘We’re running a full operation here, just like you do, with our automation equipment doing 13,000 pallet positions.’”

The in-house facility is equipped with advanced technology such as self-driving forklifts (commonly known as automated guided vehicles) and an accompanying fleet management system that coordinates their movements, cutting-edge automated storage and retrieval systems, and 10 ASRS cranes situated in the center of the racks that automatically put full pallets away without the need for operators to be in or near the equipment. Sophisticated warehouse management systems and controls make it all work. In addition to being a key part of the UMH compound, the impressive facility is an inventive and efficient revenue-generating tool that wows potential customers.

“Everybody is focused on automation these days,” Bartlett said. “A lot of people say they can sell automation, but there are a limited number of companies that can actually do it. It’s important for us to show that we can; I’ve always worked this way, proving to myself that I can do whatever a customer needs before telling them I can do the job.” UMH is designed to put their customers first, and that means only making promises they can keep. “We put ourselves in our customers’ shoes to understand how they would operate their own facility. Because we know what our systems can do, we’re able to build their facility correctly,” he added.

A laser focus on safety is central to UMH’s success. Every automated system has devices in place to ensure its smooth and safe operations. Modern forklifts, for instance, automatically sense objects or people that get in the way and either stop or reroute its path to avoid them. Cranes are programmed to shut down before humans can access them. “At the end of the day we want all of our people, our workers, contractors, and everybody in our operations to get home. That's the most important thing,” he stressed.

Bartlett and his team have great expectations for their young, rapidly rising company. “Our plan is to change the material handling industry to push the boundaries of automation and smart warehousing to the next level and build a better future.”

United Material Handling manufactures and designs the highest quality of products available in the material handling industry.

As a result, we can offer unique solutions to our customers.

We offer a full line of products including Selective Rack, Double Deep Rack, Push Back Rack, Drive In Rack, Pallet Flow Rack, Pallet Shuttles, Cantilever Rack, and Carton Flow products.

We specialize in Warehousing, Distribution, Archive and Record Storage, Grocery and Beverage Distribution, Retail, Pharmaceutical, and Manufacturing.

Corporate Office

United Material Handling

23900 Brodiaea Ave.

Moreno Valley, CA 92553

Telephone 866-323-7225

Email info@unitedmh.com

Website https://www.unitedmh.com/

Facebook https://www.facebook.com/UnitedMaterialHandling

Twitter https://twitter.com/UnitedMH

LinkedIn https://www.linkedin.com/company/united-material-handling

YouTube https://www.instagram.com/united_material_handling/