View This Article in BOSS Magazine

Quality and innovation are the hallmarks of Ulterra’s PDC drill bits, and they just keep getting better

During Covid-19 there were very few supply chains that did not experience some adverse effects. For the oil and gas industry, things were already a bit haywire, with OPEC cuts that saw the organization’s share of global crude production fall 39%. Then came the major slowdowns of the pandemic, the supply chain upheavals of a restart, and the labor tumult as the economy got back in full swing. Through it all, Ulterra remained the leading independent supplier of PDC drill bits for the industry. The company has been at the forefront of change before, focusing on PDC bits at a time when most operations still used tricone bits. They saw what the future held then, and they’re doing it again now with a digitalization process that will provide newfound efficiencies in the back office and on the manufacturing floor, putting an industry leader even higher above the competition.

Ebb and Flow

The demand for bit designs and material technology (in the form of PDC cutters) has increased exponentially over the last 20 years. During that time frame, Ulterra answered the call, becoming a leader in the space.

“As we’ve grown, we’ve seen expansion globally, adding more equipment and people,” supply chain director Brian Hilburn told BOSS. “Along the way, we continuously develop and refine our processes that make our product what it is, and Ulterra a household name in our market.”

When the pandemic struck, the usual hum of global activity suddenly went silent. Less demand for oil meant less demand for drill bits. As the world began to emerge and economic activity ramped up toward the end of 2021, “It was like somebody flipped a switch and everybody was back in business and wanted product immediately,” he said.

But with supply chains in disarray, Ulterra’s material suppliers struggled to send inventory to keep up with demand. As that started to level out, Ulterra found itself with a shortage of labor. Try as the company might to keep its labor force during a downturn, this one had been unprecedented.

“After we changed up our pay scale, we changed up what we were offering our employees as far as incentives to come work for Ulterra,” Hilburn said. “We were finally able to get individuals in the door and we started getting a good supply of candidates that we hired and put to work.”

Finally, by the third quarter of 2022, Ulterra was back to what it considered fully staffed and some semblance of normal. But the company did not spend that time sitting back and wishing for things to get better. Ulterra introduced systems to keep it nimble and agile no matter what the future brings.

Staying Lean & Agile

“We’ve always been very good at what we do, and we’re very agile,” Hilburn said.

To keep things that way, Ulterra realized the back office and manufacturing floor could replace antiquated systems to make things run more efficiently. There’s huge potential for a value boost there, considering Ulterra does all its manufacturing and product engineering in-house and turns out over 6,000 unique full-size drill bits annually.

“Our manufacturing can be thought of as rapid prototyping at scale. Each individual part is ordered on-demand using just-in-time inventory,” he said. “We produce both machined steel and cast matrix body bits and can produce the same bit in either format.”

To manage labor constraints and avoid them being a problem in the future, Ulterra is looking at what in its manufacturing process it can automate. The company has developed custom programs and software automation tools to expedite the engineering process and computer-aided manufacturing.

Anything that can reduce cycle time and prevent quality issues is a welcome enhancement when you’re dealing in the kind of volume Ulterra does.

“These software developments decrease code times on our machines and look for improved toolpaths that allow that machine to operate faster and more efficiently,” he said.

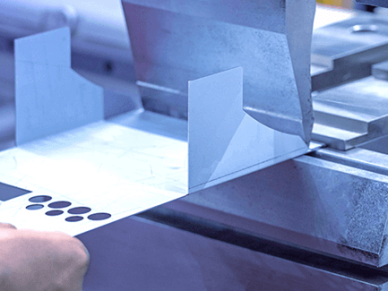

They’ve also been introducing modern advances in five- and six-axis CNC machining, keeping up with developments in the machines and in software, always with an eye to finding efficiencies and cutting cycle time without sacrificing quality. One advantage is using graphite to build the molds for matrix PDC bits.

“We found that material is readily available, and it allows our machines to work faster than some other materials to build molds out of. So, we look at the materials when we plan our production or our manufacturing process, any changes that we're going to make in our manufacturing process, what materials can we look at that could save us time as well as money.”

Any edge helps, and as Ulterra says, every run counts.

Responsiveness and Innovation

The direct beneficiaries of all these enhancements are Ulterra’s customers.

“We're high volume, high variance manufacturing and we manage that demand daily,” Hilburn said. “On average, we’re processing 100 bits daily through our facility here in Fort Worth alone, and at different sizes and types. We can do that regardless of the product mix, extremely fast at very high volumes.”

Each morning, the leadership team at Ulterra’s Fort Worth manufacturing facility have a meeting with sales representatives in each of their districts and go over what products they need. They get that product out by that night or the next day.

“We're data-driven, customer-centric, and keep lean inventory,” he said. “The data that we gather from our process internally, our customers, our performance, all of those things allow us a rapid response time to the market.”

Ulterra has built the business around its manufacturing and remanufacturing strengths to get products into the field quickly. Most of the market is rental, so when customers are finished with bits, they send them back to Ulterra, which repairs and remanufactures, getting them back to work quickly.

“Being lean, leveraging with a lot of our manufacturing software, and being agile has allowed us to be who we are, able to respond much faster to the customer versus our competitors.”

That flexibility allows Ulterra to field test new materials vendors might offer, always remaining on the cutting edge of industry innovation. It allows company engineers to redesign products on the fly when customers have specific needs that existing products don’t meet, often turning around the new design in less than a week.

“Much of our business and success can be attributed not only to a superior performing drill bit, but also the service that comes with it,” Hilburn said. “More than provider, we are a drilling partner with our customers and offer quick and full logistic, operational, and engineering support for our customers.”

The last few years have brought some drastic changes, and there may be more in store in the next few. With its agility and adaptability, Ulterra will be ready.

Ulterra is a forward-thinking drilling partner whose purpose is to empower people to advance the oil field. Ulterra’s innovative drill bit technologies take on any application to lower drilling costs, reduce non-productive time and mitigate risk. Widely recognized as the fastest growing oil and gas drill bit company in the world and largest in the North American market, Ulterra is the bit supplier of choice when drillers require a partner with unmatched credibility and a commitment to excellence.

Ulterra is unique in its flexibility and rapid-prototyping approach to challenging drilling dynamics in all applications. Ulterra can respond to customers’ specific drilling needs with customized solutions for optimized performance. Our strength resides in the experience and wisdom culled from industry veterans combined with our culture of innovation and entrepreneurship. Ulterra takes pride in designing, manufacturing, and repairing only premium-quality, high-performance PDC bits for a global market. With over 600 employees spanning major drilling markets around the world, Ulterra strives to earn your trust first and then your business through speed, innovation, and consistent performance.

Corporate Office

201 Main Street, Suite 1660

Fort Worth, TX 76102

Phone Number: 1-844-ULTERRA (858-3772)

Email: info@ulterra.com

Homepage Link: https://ulterra.com/

Facebook: https://www.facebook.com/Ulterra/

Twitter: https://twitter.com/UlterraBits

LinkedIn: https://www.linkedin.com/company/ulterra-drilling-technologies-l-p-/

Instagram: https://www.instagram.com/ulterra/

YouTube: https://www.youtube.com/c/UlterraDrillingTechnologies