Consumers want things fast, hyperlocal supply chains deliver

Like Veruca Salt wandering through Willy Wonka’s chocolate factory, today’s consumers see things they want, and they want them now. Even Veruca’s overindulgent father couldn’t snag her a golden goose, and she ended up falling down a garbage chute. She might have done better with a smartphone, because today’s ecommerce shoppers are finding more products available to them with fast delivery. Just like Veruca, they don’t care how, they just want it now. The how, though, is a fascinating study in building hyperlocal supply chains using data analytics to predict what buyers will want, making sure it’s close to them, and showing them when they can expect it through every step of the order process.

New Fulfillment Models

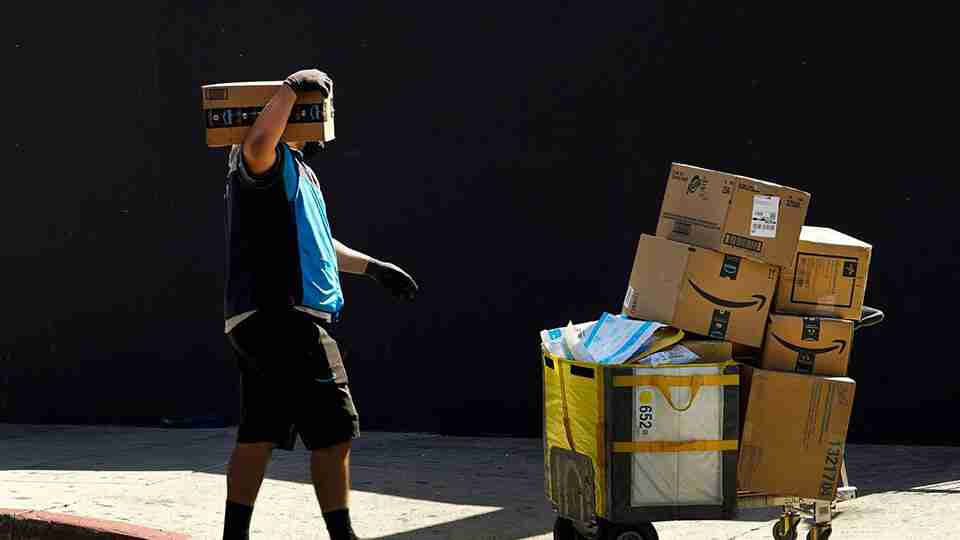

Outfits big and small are building hyperlocal supply chains, but when it comes to industry innovation like this, it’s always helpful to examine what titans like Amazon are doing. The ecommerce leader revamped its fulfillment model from a national to a regionalized one that divides the U.S. into eight interconnected regions in smaller geographical areas, each with its own main fulfillment center. The new system cuts way down on the amount of cross-country shipments Amazon has to make when a local fulfillment center doesn’t have a product in stock. Using its own Amazon Web Services, the company analyzes demand for certain products in particular areas, making sure those regional centers are well-stocked with items in high demand. This allows for more customer-pleasing features such as next-day or same-day delivery while cutting costs and environmental impact for Amazon.

“Shorter travel distances and fewer touches mean lower cost to serve,” CEO Andy Jassy said on a third-quarter earnings call last year. “But perhaps most importantly, shorter distances and fewer touches mean that customers are getting their shipments faster. We remain on pace to deliver the fastest delivery speeds for Prime customers in our 29-year history.”

Organizations are rushing to create similar systems on a smaller scale, building hyperlocal supply chains by using products that are sourced and made in specific areas, down to a neighborhood level. Machine learning and optimization algorithms help partners across supply chains keep the right amount of inventory on hand. In the last mile, machine learning is optimizing delivery routes.

“Some companies are even going to the granular level,” Subodha Kumar, founding director of the Center for Business Analytics and Disruptive Technologies at Temple University’s Fox School of Business, told BOSS. “They tell their drivers, ‘Oh, park on this side of the road and walk to the other side.’ Or, ‘Take a U-turn and come back.’ They are using this real-time data to do that, and most of this is run by AI machine learning-based algorithms.”

Picking Up Speed

SaaS platforms such as Cogsy and Zoho provide real-time inventory management for warehouses, while others like Shipday and Dispatch Science allow shippers to show customers how to track their orders, seeing how many stops away they are and getting approximate delivery times. With hyperlocalization, the entire supply chain is close to both the buyer and the seller. These factors add speed and trust to the delivery process, two important factors in winning long-term business.

It’s even changed the design of grocery and retail stores and restaurants, with special areas dedicated to picking up online orders. Food and beverage microfactory builder Relocalize is looking to eliminate some links in the supply chain.

“This is a big step towards a truck-free future for our food system. It reflects both the urgent need to decarbonize food production and the high market demand for sustainable and affordable products,” CEO and co-founder D. Wayne McIntyre told Betakit. “So if you compare that to, say, the Tesla semi, their approach is to electrify that middle mile; our approach is to make it go away completely by making the food at the point of distribution,” he said.

In the long term, Relocalize’s vision is to eliminate long-haul food transportation altogether by hyperlocalizing the production and distribution.

Farm Fresh

Naturally, one might expect hyperlocal supply chains to work better in densely populated urban areas. There are a lot of people with similar needs packed into a compact space. In rural Wisconsin, though, Fork Farms and the Marshfield Clinic Heath System are creating them to combat a particularly vexing problem. Though rural areas grow most of the food in the U.S., their residents are more likely to be food insecure than people in large cities.

At community hubs in Rusk County, where more than 20% of children are food insecure and where 96% of families qualify for income-based nutrition programs, Fork Farms is setting up hydroponic farming equipment, and conducting educational programs on nutrition, innovation, and sustainability. Marshfield Clinic is funding the pilot program and arranging for places such as senior centers, daycare centers, thrift stores, and schools to host the programs.

Fork Farms describes its model as “the most efficient, scalable, and transformative hydroponic technology on the planet.” One of its Flex Farms can grow 25-plus pounds of food every four weeks with just 2 hours of maintenance per month, allowing home growers to harvest 3,400 plants a year.

In India, Doodhvale is using hyperlocal supply chains to deliver dairy products direct to consumers who order via an app mere hours after the milk has been squeezed.

“This benefits both customers and businesses by enhancing the overall commerce experience and staying ahead in a highly competitive market,” co-founder Aman Jain told India.com.

It might not be your own golden goose, but with hyperlocal supply chains, companies can deliver your order now.

Leave a Reply