Artificial intelligence (AI) is revolutionizing the manufacturing sector, bringing unprecedented efficiency and innovation. The integration of AI technologies into manufacturing processes is reshaping how products are designed, produced and delivered. As a business professional, understanding these advancements can offer you a competitive edge.

The integration of artificial intelligence in manufacturing is not just a trend; it’s a transformative shift that is redefining the industry. By leveraging AI, companies are able to optimize production lines, predict maintenance needs and enhance quality control. This article explores the critical role AI plays in modern manufacturing and why staying informed about these advancements is crucial for business success.

Optimizing Production lines

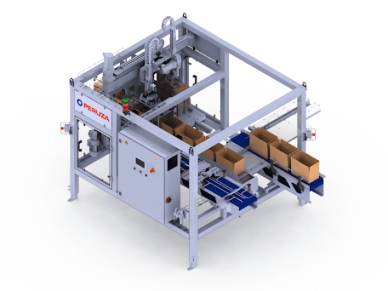

One of the most significant impacts of AI in manufacturing is the optimization of production lines. AI algorithms analyze vast amounts of data to streamline operations and improve efficiency. This means, in the process industry, predicting equipment failures before they happen, minimizing downtime and reducing costs. What’s more, AI systems can dynamically adjust production schedules based on real-time data, ensuring that resources are used most effectively.

Implementing AI-driven automation also helps in maintaining consistent product quality. For instance, machine learning models can identify defects or deviations from standards early in the production process. This proactive approach not only saves time but also ensures that the final products meet high-quality standards. As a result, manufacturers can reduce waste and increase customer satisfaction.

Enhancing Predictive Maintenance

Predictive maintenance is another area where AI has made substantial contributions. Traditional maintenance strategies often involve scheduled checks or reactive repairs after a breakdown occurs. However, AI enables predictive maintenance by analyzing sensor data to forecast when equipment is likely to fail. This shift allows manufacturers to address issues before they escalate into major problems, ultimately saving time and money.

For instance, sensors embedded in machinery collect data on various parameters such as temperature, vibration and pressure. By processing this data through AI algorithms, patterns indicating potential failures can be detected early on. Consequently, maintenance can be performed precisely when needed rather than on a fixed schedule or after a failure occurs. This approach not only extends the lifespan of equipment but also ensures smoother operations.

Improving Quality Control

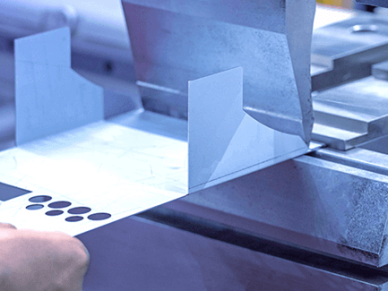

Quality control is paramount in manufacturing and AI offers significant advancements in this area. Traditional quality control methods often rely on manual inspection or random sampling, which can miss defects or inconsistencies. AI-powered systems, however, can continuously monitor production and identify even minor anomalies in real-time.

Computer vision technology, for example, combined with machine learning algorithms can inspect products at a speed and accuracy far beyond human capabilities. These systems can detect imperfections such as cracks, discolorations, or incorrect dimensions instantly. By catching defects early in the production process, manufacturers can prevent faulty products from reaching customers and maintain high standards of quality.

The Future of AI in Manufacturing

The role of AI in modern manufacturing processes is expected to expand even further as technology advances. Emerging trends such as autonomous robots, intelligent factories and advanced analytics are set to drive the industry forward. Autonomous robots equipped with AI can perform complex tasks with precision and adapt to changes in the production environment seamlessly.

Intelligent factories leverage IoT devices and AI to create highly interconnected systems where machines communicate with each other to optimize workflows automatically. Advanced analytics provide deeper insights into production processes by analyzing big data generated during manufacturing. These insights enable continuous improvement and innovation within the industry.

Summing Up

Staying updated on these technological advancements is essential for any business professional aiming to remain competitive in the rapidly changing manufacturing landscape. By embracing AI technologies, companies can achieve greater efficiency, reduce costs and deliver higher-quality products to their customers.

Leave a Reply