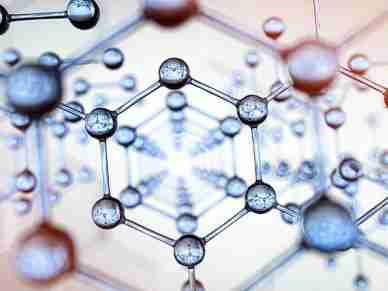

Nickel used in lithium-ion batteries that power electric vehicles must be 99.8% pure

A global nickel shortage is causing a problem for automobile manufacturers working to improve their fleet of electric vehicles, with the mineral being an integral part of their lithium-ion batteries.

The shortage is not the result of a lack of nickel, but instead because there are not enough mining projects or facilities that are able to process the type of nickel needed for batteries used by EVs.

At the same time, the amount of nickel needed for an EV lithium-ion battery is increasing, since the more nickel it contains makes it more energy dense.

The type of nickel that goes into an EV battery also has to be of higher quality than what is typical, needing a purity of at least 99.8% and a classification of “class one.”

″We’re heading towards, you know, 90 percent of the cathode being nickel for certain specific cell types,” Benchmark Mineral Intelligence’s Mark Beveridge told CNBC.

Russia’s invasion of neighboring Ukraine has been a part of the problem, with the Kremlin owning a large amount of high-grade nickel.

Prices for nickel skyrocketed following Russia’s unprovoked aggression, over fears the conflict would cause disruptions in the supply chain.

The London Metal Exchange, fearing such disruptions, even suspended the trading of nickel for a period of a week, reports CNBC.

In the U.S., domestic nickel resources are in decline, with the country’s primary nickel mine in Michigan expected to be closed down in the year 2025.

The majority of nickel is currently used by the stainless-steel industry, and, while Beveridge estimates batteries only make up around 10% of the demand for the mineral, he says he expects that to increase going forward.

″If we go forward 10 to 15 years, we’re actually looking to a future where the battery sector could provide more than 50 percent of the demand for nickel units by that time,” Beveridge told CNBC.

Leave a Reply